In Ancient Rome it was custom that in public buildings one could find the track of the architect who created the construction; just like the Pantheon at Rome (despite some doubt it): the façade inscription «M.AGRIPPA L:F: COS TERTIVM FECIT» is the best proof that he built it. Likewise, painters sign their works to testify about who created them, like in 1931 did the famous Spanish painter Salvador Dalí on his work The Persistence of Memory. On their part, clothes designers do the same to identify their garments, and such is the case of the designs belonging to the famous brand Armani. Do you see a pattern in this? I’ll give you a hint: traceability, that possibility of «identifying the origin and the different stages of a production and distribution process of consumer goods» (according to the definition of the Spanish Royal Academy’s Dictionary). And today this is our theme of STI Wednesday, although we won’t talk to you about fashion or art, but food safety and quality control of diverse products.

A detailed description of a process

According to the Spanish Food Safety and Nutrition Agency, traceability consists of being able to «find and follow the track, through all production, transformation and distribution stages of a foodstuff, a feed or ingredient». This technology is also defined as «the ability of producers, industrialists, traders, consumers and public authorities of being able to follow the track of a specific object throughout all or part of its useful life». Here, we must notice that in the past the Spanish Language Academies used to recommend the usage of trackeability instead of traceability, however, the Spanish Royal Academy decided, in its twenty-third printed edition (2014), that the correct word would be traceability, given that prevailed the influence of English language.

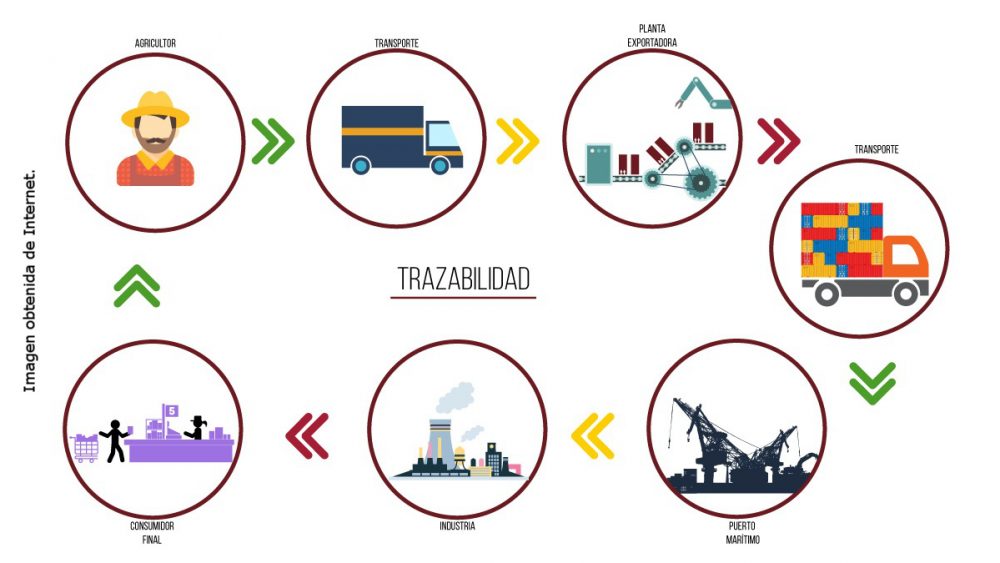

Having said that, traceability can be considered from three different types of focuses:

- Ascendant traceability (backwards). Consists of distinguishing the products received at the business, with information on who produced them and where they come from.

- Intern or process traceability. Is the product’s move within the enterprise that produced it.

- Descendant traceability (forwards). Consists of identifying the products produces by the enterprise and knowing which destiny they are going to and who the clients are.

One of the main development areas of traceability is food safety, which fundamental objectives are: information, processing and identification of the products, through the monitoring from the production chain beginning until the product reaches to the consumer’s plate. All this, aiming to guarantee both quality and safety of the products being consumed.

From functioning perspective, traceability provides a better monitoring and control of the product, in the search of avoiding frauds by recognizing their characteristics and applied processes: producers identify their crops work and treatments employed, so they can fulfill quality systems; elaborated industry and distribution apply quality control systems, labeling, maintenance in cold, agility in transport and storage; meanwhile the consumers are in charge of using and keeping the products they acquire.

The diverse fields in search of a better quality control

Did you intoxicate yourself with some foodstuff and you don’t know where it comes from? Good thing is the food sector is the main work field of traceability, and there lays its importance, given that it facilitates the monitoring of products at any stage of their production, so you can know where they came from and what kind of safety problem is the one you are facing. Food included are: fish, from direct fishing, maritime and continental, like aquaculture, this one we can consider a full traceability, due to the fact that the history of the product is known, different to those from sea or river, where diseases can appear or there might be pollution; meat of livestock species, for which traceability is practically a requirement that serves as guarantee to the consumer, due to problems like encephalopathy, glossophage, swine fever, clenbuterol, etcetera; vegetable products, where we find a variety of traceability types, thanks to the different ways of conditioning, transport and commercialization, by the existence of perishable and non-perishable products, of which both need to fulfil specific safety norms or certificates of the producers.

But the concept is not implemented just for foodstuff, is so versatile and limitless that other industries are providing added value to their product by applying traceability. In the pharmaceutical market the consumer will know at what moment and who produces the medication, as well as its expiration date and the whole process it goes through until reaching the final consumer. On the other hand, at mining industry, in Europe the norm REACH rules, which intention in knowing the origin and process of the minerals being exported, that thanks to traceability are known immediately. There also exists the documentation, which consists of registering the track left by the document during the process of any procedure; this includes banks, customs houses, institutions and many others. In addition to those aforementioned, traceability is present in areas such as construction, management systems and health services.

Traceability’s privileges and obstacles

Nowadays the market is very competitive, it is saturated of products and brands, which makes more and more complicated to get a loyal consumer; in this sense, traceability is a great allied to keep the costumer, since it provides the certainty of a scrupulously kept record of the product being consumed. Among the advantages of implementing this system for an enterprise we find:

- Increasing the quality of the product, as well as the brand’s image.

- Supporting the product’s origin.

- A source of investment is not necessary for its development.

- Approaching new technologies to the primary sector.

- Causing progress in the sector it is used.

- Taking to the realisation of collaborative processes among supplier, producer and customer.

But it ain’t all benefits and advantages, there are also disadvantages and difficulties that cause these technologies not to develop in the better way, here are some:

- Sometimes, traceability is a difficult aspect to determine.

- It requires a responsibility that not every enterprise is willing to take.

- In some cases, it is applied in sectors that have a low technological development.

- There are still some political, economic and socio-cultural constraints that avoid adoption and development of traceability.

Now then, an interesting and important datum is: after the approval of the Food Safety Modernization Act belonging to the US Food and Drug Administration, the producers who want to export to the USA will have to adapt to the requirements of this new law. The above comes to help Sinaloa state both in food security and in economy, since about 80% of our exportations go to our north neighbor, of which most are agricultural products. Don’t you feel even more comfortable when consuming Sinaloense products now you know about this norm?

Written by Alfredo Careaga (Communication and Diffusion, PIT-UAS), translated by Belem Ruiz (Edition and Communication, PIT-UAS).

Parque Científico Tecnológico, Universidad Autónoma de Sinaloa © 2015

Parque Científico Tecnológico, Universidad Autónoma de Sinaloa © 2015